Energy Efficiency Programme Office (E2PO) has identified the following implementations to develop a holistic energy efficiency plan for Singapore:

- Promote the adoption of energy efficient technology and measures by addressing the market barriers to energy efficiency;

- Build capacity to drive and sustain energy efficiency efforts, and develop the local knowledge base and expertise in energy management;

- Raise awareness and reach out to the public and businesses to encourage energy efficient behavior and practices; and

- Promote R&D to enhance Singapore’s capability in energy efficient technologies.

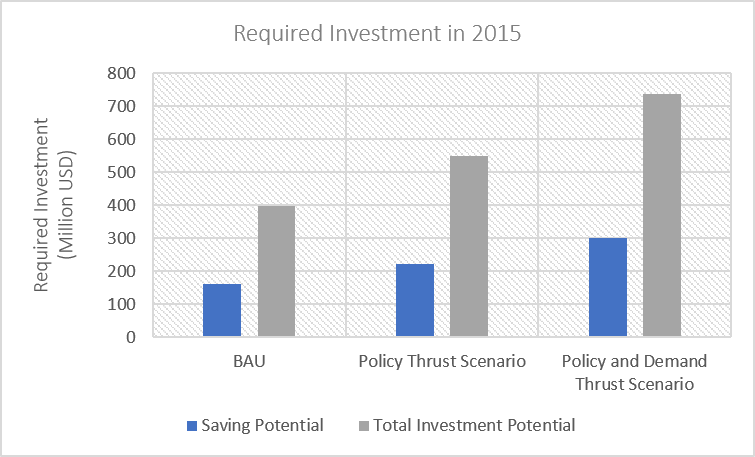

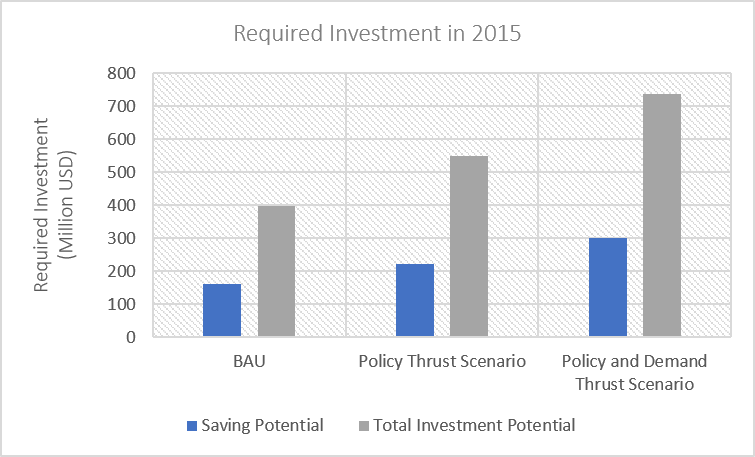

As the industrial sector makes up about half electricity consumption share, the vast opportunities for energy efficiency improvements are plausible. The required investment for industrial energy efficiency in 2015 is estimated at USD 397 million to USD 739 million, depending on policies and demand push. Singapore has various financial schemes to finance EE projects such as the E2F) for the industrial sector and the GMIS for the building sector. The range of market potential is shown in Figure 7 below:

Required Investment in industrial energy efficiency based on scenario

Source: E2PO Singapore

Source: E2PO Singapore

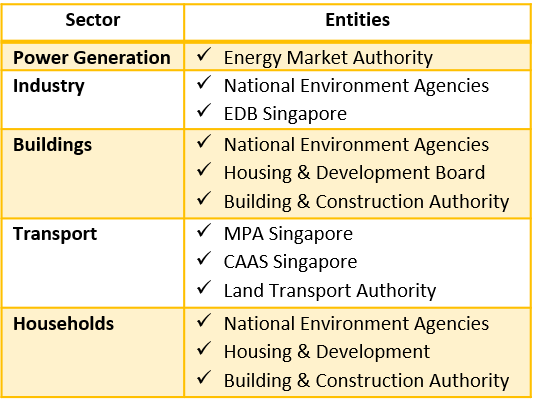

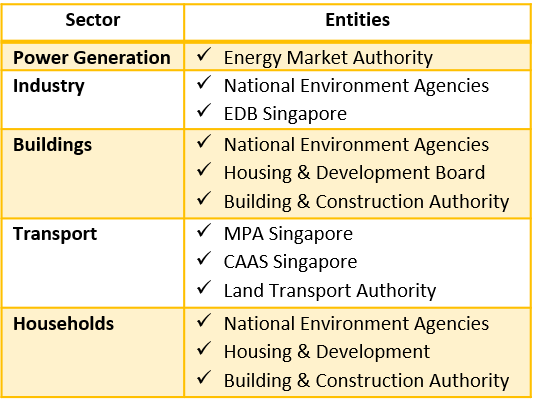

The E2PO is a multi-agency committee that jointly promotes and facilitates the activities of energy efficiency in Singapore. Table 1 below is showing whole of related government entities to improve energy efficiency in Singapore:

Related government entities to improve energy efficiency in Singapore

Source: E2PO Singapore

Source: E2PO Singapore

Since 2017, National Environment Agency (NEA) established Energy Efficiency Fund (E2F). The objective of E2F is supporting industrial companies to design resource efficient facilities, conduct energy assessments to identify energy efficiency measures, and adopt energy efficient equipment or technologies. The Energy Efficiency Fund (E2F) supports the following implementations on business to improve energy efficiency of industrial facilities:

- Resource Efficient Design

Companies setting up new industrial facilities in Singapore are encouraged to integrate energy and other resource (e.g. water, gas) efficiency improvements into the design of the facility. Design workshops are focused and collaborative efforts to design facilities to be energy efficient. The E2F co-funds up to 50% of the cost of a design workshop or USD 600,000 whichever is lower.

- Energy Assessment of Existing Facilities

Companies are encouraged to carry out energy audits on operating industrial facilities to identify and quantify areas where energy savings can be made and estimate the amount of savings achievable. The E2F co-funds up to 50% of the costs of such energy audits, subject to a cap of USD 200,000.

- Energy Efficient Equipment

Companies operating new and existing manufacturing facilities are encouraged to invest in energy efficient equipment or technologies. The E2F co-funds up to 30% of the investment cost of energy efficient equipment or technologies

Source: National Environment Agency

Source: National Environment Agency Source: E2PO Singapore

Source: E2PO Singapore Source: E2PO Singapore

Source: E2PO Singapore Source: E2PO Singapore

Source: E2PO Singapore